2022-07-16

Basket filter instructions for use

Basket filter is used for oil or other liquid pipeline, filtering debris in the pipeline, filtering pore area than the diameter of the pipe area is greater than 2-3 times. The filtering area is much larger than the filtering area of Y-type and T-type filters. The filter accuracy is one of the best filters in the filter, and the structure of the filter is different from other filters, because the shape is like a basket, so it is called blue filter.

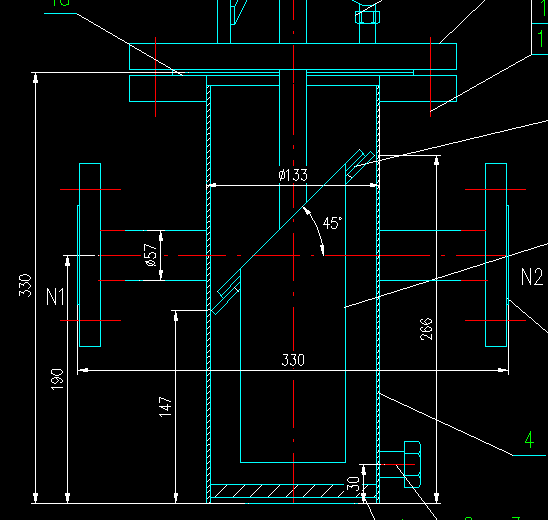

Basket filter is mainly composed of receiver, cylinder, filter basket, flange, flange cover and fasteners. Installed on the pipeline, it can remove larger solid impurities in the fluid, so that machines and equipment (including compressors, pumps, etc.) and instruments can work and operate normally to stabilize the process and ensure safe production.

When the fluid enters the filter barrel with a certain specification of screen, its impurities are blocked and the clean filtrate is discharged from the filter outlet. When cleaning is required, it is only necessary to remove the removable filter barrel and reload it after processing, therefore, it is extremely convenient to use and maintain. It has been widely used in petroleum, chemical, pharmaceutical, food, environmental protection and other industries. If it is installed in series at the inlet of the pump or other parts of the system pipeline, the service life of the pump and other equipment can be extended, and the safety of the whole system can be ensured.

Principle of operation

Pipeline in the installation will have other debris brought into the pipeline, in the production of raw materials also contains debris. When the liquid in the pipeline passes through the filter, its dirt is collected by the filter into the screen, and the pressure is released through the pressure relief hole at a certain level, so that the screen can be cleaned by easily opening the shell cover, and the shell can be cleaned through the stagnant discharge port.

General principles of filter selection.

1. Import and export diameter.

In principle, the import and export diameters of the filter should not be smaller than the import diameter of the matching pump, and should generally be the same as the diameter of the import pipeline.

2. Nominal pressure.

In accordance with the highest possible pressure of the filter line to determine the pressure level of the filter.

3, the number of holes to choose.

Mainly consider the impurity particle size to be intercepted, according to the media process process requirements

Scope of application

1.Chemical and petrochemical production of weakly corrosive materials, such as: water, ammonia, oil, hydrocarbons, etc.

2.chemical production of corrosive materials, such as: caustic soda, concentrated dilute sulfuric acid, carbonic acid, acetic acid, ester acid, etc.

3.refrigeration in the low temperature materials, such as: liquid methane, liquid ammonia, liquid oxygen and a variety of cold agent.

4.light industry and food, pharmaceutical production of materials with health requirements, such as: beer, beverages, dairy products, grain pulp medical supplies, etc.

5. a variety of special processes, such as high-efficiency filters.

Repair and maintenance

1、The core part of the filter is the filter core, the filter core consists of the filter frame and stainless steel wire mesh, the stainless steel wire mesh is a wearable part and needs special protection.

It needs special protection.

2、After the filter has been working for a period of time, certain impurities will be deposited in the filter core, and the pressure drop will increase and the flow rate will decrease.

Clear the impurities in the filter core.

3, when cleaning impurities, pay special attention to the stainless steel wire mesh on the filter core can not be deformed or damaged, otherwise, the damaged filter core, will make the filter

after the media purity does not reach the design requirements, compressors, pumps, instruments and other equipment will be damaged.

4、If the stainless steel wire mesh is found to be deformed or damaged, it should be replaced immediately.