2021-10-26

Why does the circulating cooling water system use a shallow sand filter as a side filter?

Protecting the water environment and preventing wastewater pollution is an important part of the battle for pollution prevention. In the field of industrial circulating water, the recycling of water resources is the general direction, principle, and logic!

In the field of industrial circulating water, there are usually various problems such as slime, scale, silt deposition, etc. These problems directly lead to a reduction in heat exchange efficiency, and will increase consumption, block pipelines, and shorten the use of equipment. life.

The shallow sand filter independently developed by Lifeierte can effectively solve these problems and ensure the efficient, stable and safe operation of the circulating cooling water system.

1. What is a shallow sand filter?

The shallow sand filter is composed of one or more standard high-speed filter units. The water flows through the internal water distributor and water collector, using different media, which can effectively remove particles and reduce turbidity.

Lifeierte adopts a modular design concept, makes full use of the principle of fluidics, and adopts imported brand Bermet/Donott automatic control valves and control systems to realize the fully automatic operation of the entire filter system.

2. What are the characteristics of shallow sand filters?

The Lifeierte shallow sand filter has the characteristics of small footprint, low backwash water consumption, no dead zone, and flexible product use. It is an indispensable equipment for the circulating water side filter system. The backwash water source can be selected from the system, the water tower or the external water source, and can be automatically switched; the filter unit size is 20"-56" optional; the material is carbon steel and stainless steel.

3. Why should a shallow sand filter be used in the circulating cooling water system?

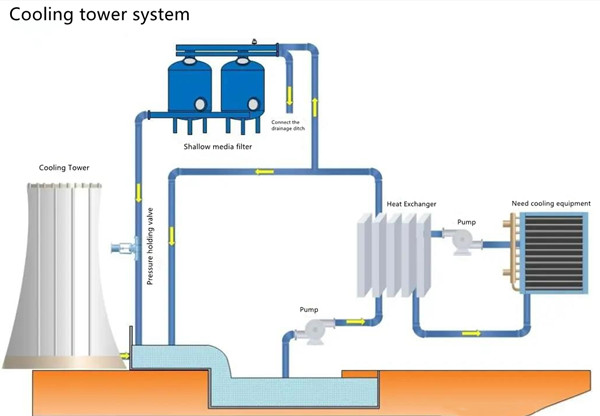

Because the circulating cooling water system is an open system, dust, impurities in the air and scale in the pipeline will enter the water and make the water quality worse. When the impurities increase, it is easy to block the copper tube of the heat exchanger, reducing the heat exchange rate and affecting the whole Cooling system effect.

Compared with traditional filters, shallow sand filters have the following advantages: uninterrupted water supply to the system during backwashing, low water consumption for backwashing, small footprint, no need for special foundation treatment, automatic control, simple maintenance, and effective To reduce turbidity, shallow sand filters are the first choice for working conditions where the circulating cooling water flow is large and the filtering speed is faster.

4. Why do side filtering?

Cost: The circulation volume of the cooling system is generally relatively large, and the cost of full filtration is relatively high.

Circulation: The water system is cyclic, and the effect of side filtration is superimposed. For a long time, the water in the system has been filtered to achieve the filtration effect.

5. Which parameters are related to the flow selection of shallow sand filter?

The flow selection of shallow sand filter is mainly based on the circulation of the cooling system, generally 2%-5% of the circulation is appropriate