2023-09-12

The cartridge filter housing is a commonly used component in the pre-treatment of systems such as reverse osmosis equipment. It is usually used to protect the water inlet arrangement of the membrane and provide the service life of the membrane. Security filters can also be used behind reverse osmosis equipment and ultrafiltration equipment. At this time, they are also called microporous membrane filters. The filter accuracy at this time is usually below 1 micron. They are mainly used to intercept water after passing through the ultraviolet sterilizer. bacterial impurities.

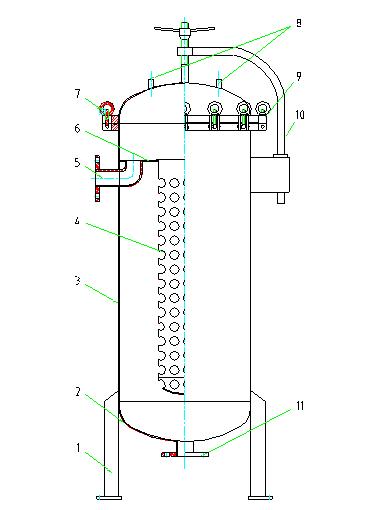

Filter structure

The filter materials formed by Baoan Precision Filter include: filter cloth, filter screen, filter disc, sintered filter tube, wire-wound filter element, melt-blown filter element, microporous filter element and multi-functional filter element. Due to different filter materials, the filter pore sizes are also different. Precision filtration is a type of filtration between sand filtration (coarse filtration) and ultrafiltration. The filter pore size is generally in the range of 0.1-120um. The same type of filter media is divided into different specifications according to appearance dimensions.

Classification of precision filters

Classification of precision filters

Stainless steel precision filters are divided into: eye nut type, clamp type, flange type. The characteristics are:

Eye nut type:

It has good sealing performance and is more convenient to replace the filter element than the flange type.

Clamp type:

It is easy to install, cheap, and the pressure resistance is less than 0.6Mpa.

Flange type:

Good sealing.

General principles for selecting security filters

1. Import and export diameter

In principle, the inlet and outlet diameter of the filter should not be smaller than the inlet diameter of the matching pump, which is generally consistent with the inlet pipe diameter.

2. Nominal pressure

Determine the pressure rating of the filter according to the highest possible pressure in the filter line.

3. Selection of hole number

The main consideration is the particle size of impurities to be intercepted, which is determined according to the process requirements of the media process. Check the table "Filter Specifications" for the particle sizes that various specifications of wire mesh can intercept.

4. Filter material

The material of the filter is generally selected to be the same as the material of the connected process pipeline. For different service conditions, filters made of cast iron, carbon steel, low alloy steel or stainless steel can be considered.

5. Calculation of filter resistance loss

For water filters, under the generally calculated rated flow rate, the pressure loss is 0.52~1.2kpa.

Security filter maintenance and repair

1. The core component of the precision filter is the filter element. The filter element is a vulnerable component and requires special protection.

2. If the precision filter works for a long time, it will intercept a certain amount of impurities, which will reduce the working speed, so it must be cleaned frequently and the filter element must be cleaned at the same time.

3. During the cleaning process, special attention should be paid to cleaning the filter element and not to deform or damage it. Otherwise, the filtering accuracy will be reduced and the production requirements will not be met.

4. If the filter element is found to be deformed or damaged, it must be replaced immediately.

5. Some precision filter elements cannot be used repeatedly, such as bag filter elements, polypropylene filter elements, etc.

Security filter installation and use instructions

1. Thoroughly clean the filter housing. to

2. The inlet and outlet of the clean shell are connected to the filtration system pipeline. Pay attention to the direction when connecting to ensure that the filter element is in the state of water inlet from the outside and water out from the inside. to

3. Open the plastic bag at the open end of the filter element and check whether the O-ring is intact and in place. to

4. Use a suitable wetting agent (such as water) to moisten the O-ring and filter element seat socket. to

5. Hold the end of the filter element close to the O-ring, and vertically insert the filter element socket into the filter element seat socket. to

6. After inserting all the filter elements, remove the filter element packaging bag, fasten the pressure plate to fix it, and then install the metal cover. to

7. Open the air release valve on the top of the housing.

8. Open the inlet valve slightly to allow the liquid to enter the housing until the liquid comes out of the release valve at the top of the housing. At this time, close the release valve.

9. Slowly adjust and open the downstream outlet valve until it is fully open. to

10. Slowly adjust and open the inlet valve until it is fully opened. At this time, the pressure drop between the upstream and downstream of the filter is 0.02Mpa (the initial pressure drop under determined flow rate).

Precautions for using security filters

1. The filters are combined and configured according to the principle of "coarse first, then fine", and the order cannot be reversed.

2. The actual compressed air flow, pressure and temperature passing through the filter cannot exceed the values specified on the nameplate.

3. When installing, pay attention to distinguish the inlet and outlet positions of the filter.

4. The filter should be installed vertically. There is a certain height above the ground for easy replacement of filter elements.

5. When one of the following situations occurs, the filter element should be replaced:

a. The filter effect deteriorates significantly;

b. The pressure difference indicates that the value exceeds 0.07MPa; (Note: the initial pressure drop of the filter element is <0.015Mpa);

c. Use time limit: FC, FT, FA are 8000h, FH is 2000h;

6. For filters without automatic drainers, the ball valve should be opened regularly to eliminate water accumulation in the filter housing. Usually no less than 1-2 times per shift;

7. The filter inlet temperature does not exceed 66°C;

Related Product recommend